How LIEBIG’s unique post-installation solution can challenge cast-in anchoring dominance

Given the perceived performance benefits, cast-in place anchoring has long been the preferred approach for structural engineers when considering applications in to concrete. However, as the LIEBIG Ultraplus has demonstrated in the project to create a new lifting bridge over the River Yare in Great Yarmouth, post-installation anchors can offer equivalent performance whilst also being better suited to the complexities of modern construction processes.

The £121m Herring Bridge project is an excellent example of how the application of innovative products can enable major civil engineering projects to be delivered more efficiently in a shorter timescale.

The project’s New York based designers, Hardesty & Hannover, who worked in conjunction with specialist consultants Roughan & O’Donovan (ROD), are no strangers to complex bridge construction having worked on projects throughout the US and Europe. But the challenges facing the team on the Great Yarmouth scheme required ‘outside the box’ thinking to satisfy the structural requirements for a bridge of this type and scale, whilst accommodating a realistic delivery schedule for the bridge’s key phases.

The twin bascule bridge construction process involved building cofferdams on both banks of the river. These house the machinery and mechanism required to lift, hold, and lower each leaf of the bridge, all of which had to be securely anchored to the concrete.

‘Real world’ practicalities versus the ‘ideal world’

As with many major civil engineering projects involving the kind of ‘design and build’ process used here by main contractors BAM Farrans, the team did not have the luxury of the ‘ideal world’ approach where anchors are cast-in to the concrete. This was primarily because the construction of the cofferdams had to commence as soon as the project received the green light, which meant there was no scope for the extended design time that cast-in anchors would have demanded.

The design team, therefore, explored the potential for a post-installation anchoring solution to attach the baseplates of the bridge’s operating mechanism. Crucially, any anchors would have to be suitable for the concrete conditions within the cofferdam design and offer a very high load capacity.

It was at this point that Yorkshire-based engineering specialists Qualter Hall were consulted to help identify a post-installation anchor that would meet this demanding criteria. Qualter Hall’s experience in delivering numerous major infrastructure projects across the UK was invaluable, and they quickly spotted the potential of LIEBIG Ultraplus anchors.

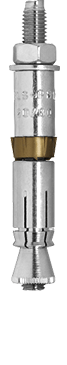

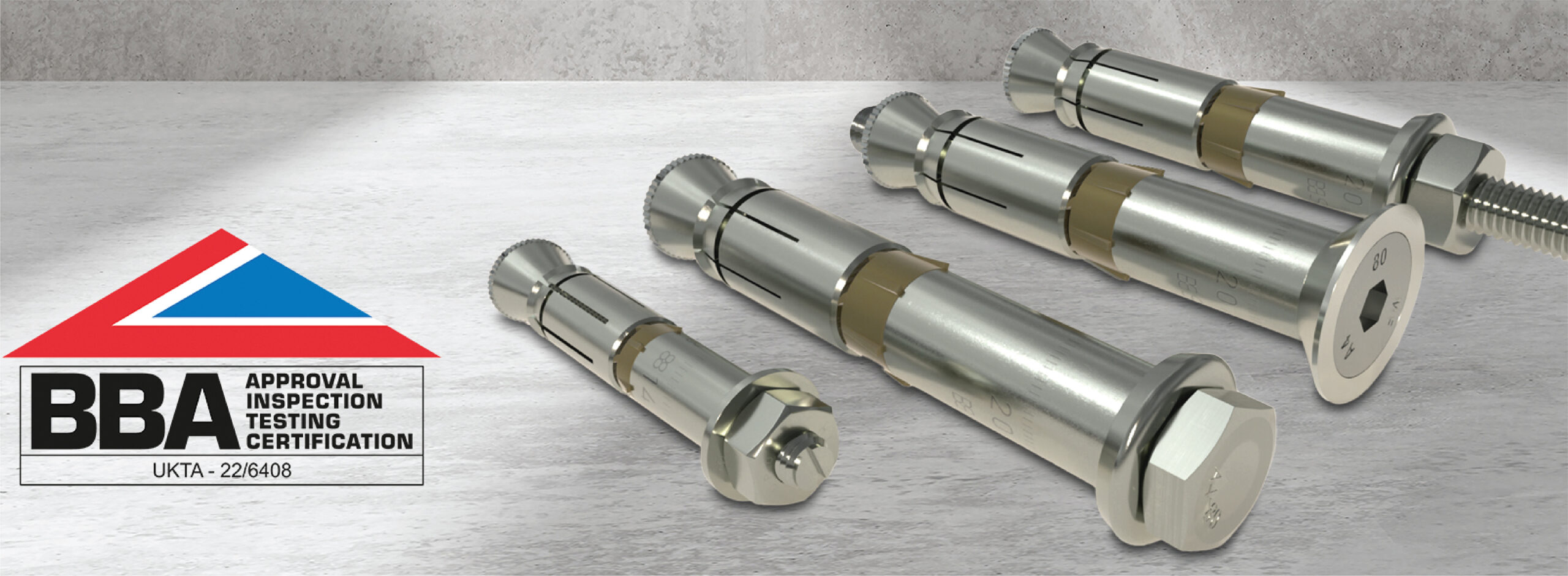

These heavy duty undercut anchors from EJOT are renowned for their ability to accommodate exceptionally high loads in cracked and non-cracked concrete. They are manufactured in high strength carbon steel and have demonstrated reliability in resisting dynamic loads, shock loads and seismic loads.

How could the post-installation anchors demonstrate compliance?

Ultraplus is an ETA (European Technical Assessment) approved heavy duty anchor which is already widely specified around the world for anchoring steel structures and baseplates into concrete. Such is its performance that it has been used extensively in sectors including nuclear power, the oil and gas industry and water treatment.

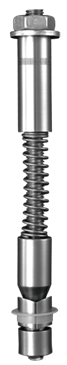

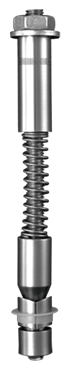

For the Herring Bridge, the design required EJOT to produce and deploy possibly the largest post installed mechanical anchors ever used in a civil engineering project. Two lengths of M36 size Ultraplus anchors were produced, with the longest being 1.45m in length and the shortest 1.09m, with both lengths being used on the same baseplates in an unconventional yet successful design approach.

It was an approach that, despite being incompatible with the ETA, did satisfy the requirements of another globally respected building standards code as EJOT UK’s anchoring specialist, Paul Papworth explained:

“The initial design proposal was to use more anchors at a shallower embedment depth, but we believed this was unsuitable because the concrete capacity would have been insufficient to support the projected forces. Given our understanding of the capabilities of Ultraplus, we supported through our design team an alternative, more unusual method of using mixed length anchors and the concept quickly gained traction within the project team.

“Whilst the ETA does not legislate for such a permutation, i.e. the use of different lengths of anchor in the same baseplate, the ACI (American Concrete Institute) Building Code does because it takes into account the additional area of resistance in the concrete which can be created by the approach. This meant our anchor specification for the Herring Bridge, in conjunction with our advised redesign of the baseplate to allow increased concrete capacity to be achieved, would be approved using a combination of different design codes.”

Replicating cast-in anchors through an innovative stress transfer design

With Ultraplus, the compression forces in the concrete mirror those of a cast-in solution rather than those of a normal post installed undercut anchor. This is due to the facing direction of the expansion segments and the fact that the undercut is on the same parallel plane to the surface of the concrete, rather than being at an angle to it.

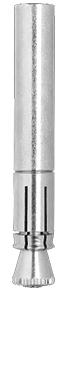

- Standard Undercut Anchor – Compression of the concrete is created by partial expansion forces being created at the bottom of the anchor.

- Typicasl Cast-in Place Anchor – Compression of the concrete is achieved between the cast-in washer plate and the concrete.

- LIEBIG Ultraplus Anchor – Compression of the concrete is achieved between the undercut and the concrete surface.

Demonstrating compliance with the ACI Building Code enabled Ultraplus anchors to be deployed in this bridge construction project with confidence and ensure a post-installation approach could be utilised. The advantages that stemmed from this meant the bridge’s design and construction time could be reduced, with subsequent cost benefits.

And while the project was not without its challenges, largely as a result of multiple components coming together ‘when ready’ rather than ‘when scripted’, Paul and the EJOT team worked to ensure any modifications or additional support requirements which arose during installation could be resolved collaboratively without having an adverse effect on the build schedule or budget.

BAM Farrans’ Lynsey McNeilly commented:

“Every project gives us an opportunity to apply what we learnt previously, but the knowledge and skills we have developed during this project could prove extremely valuable to us and all project partners.

“In terms of anchoring into concrete, the performance we have been able to achieve using the bespoke LIEBIG Ultraplus anchors, in line with the design recommendations provided by EJOT and the expertise of drilling specialists Core Cut, tells us that a post-install approach can be advantageous even where cast-in is also viable. And that could help us deliver projects like this for clients in future more efficiently without compromising performance goals.”