The unique engineering principles of the LIEBIG anchoring range

The Liebig brand has for years been synonymous with quality, performance and ease of installation, gaining respect from specifiers and contractors alike. Many of the original flagship products remain at the forefront of today’s anchoring technology.

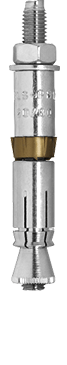

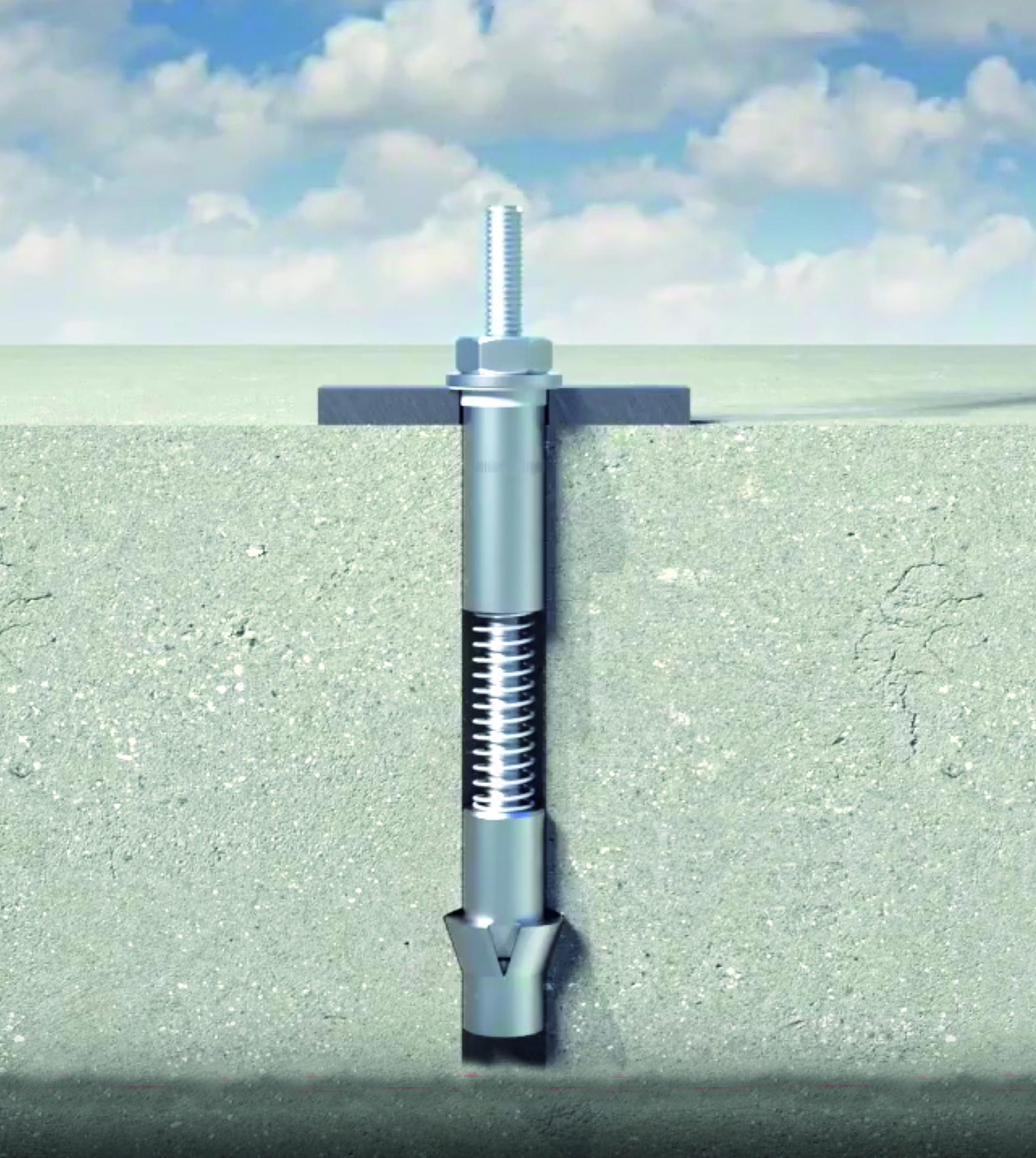

Liebig Ultraplus

Regarded as the ultimate high-performance anchor, sizes run from M12 up to M36, extending associated performance benefits beyond any other mechanical anchor, with unique features that include:

- Mechanical spring-loaded anchor setting

- Reverse undercut mechanism

- Built-in isolation between fixture and anchor

- Modularity and application-specific variants

Standard undercut anchors work by drawing a sleeve over a cone, expanding the sleeve within a void already created in the concrete by use of a special tool. Liebig Ultraplus works the opposite way, utilizing its spring-loaded mechanism so that when the expansion segments reach the void, a cone drives down into a series of shields, causing them to expand into the void. This way of creating the undercut connection provides further significant performance benefits:

- Expansion segments open in the direction of load, working like a cast-in anchor or foundation bolt

- These segments are produced from a much thicker material giving them the capability to evenly transfer greater loads

- Optimized use of the concrete capacity thus achieving higher loads

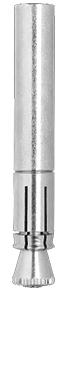

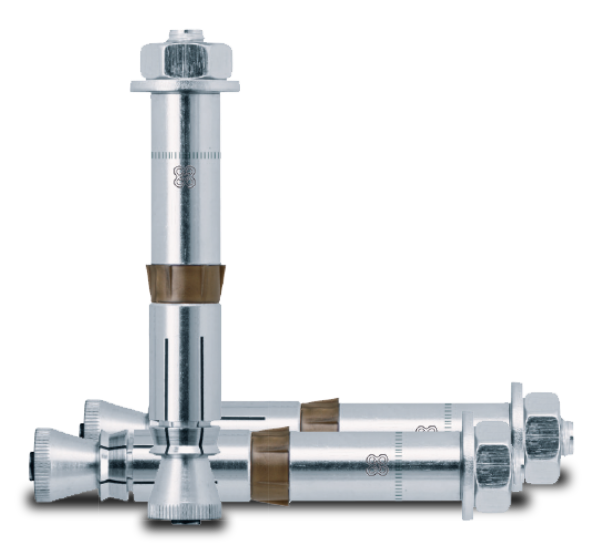

Liebig Superplus

Ranging from M8 to M16, this anchor requires no special drill bits, no maximum hole depth and no special setting tools – simplifying installation, reducing workmanship related issues, increasing productivity and reducing cost. From drilling through to setting torque, Superplus is installed like any regular expansion anchor yet offers higher guaranteed performance – making it the choice for safety-critical applications.

The anchor draws a thick-walled expansion shield over a tapered cone. The shield has biting keys ‘machined in’, creating their own undercut or key into the concrete and thus yielding very high tensile and shear performance.

The Liebig range also includes heavy duty expansion anchors:

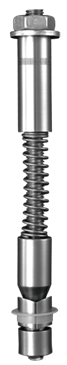

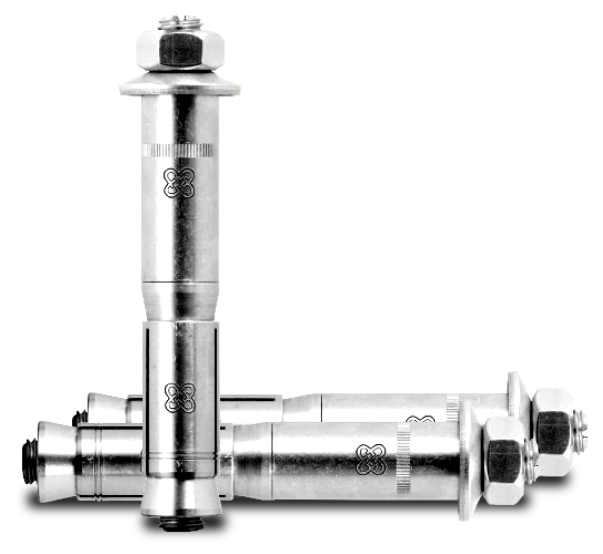

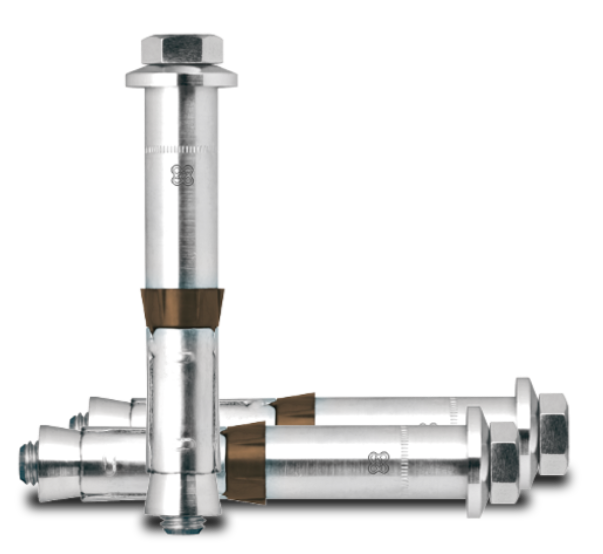

Liebig Safteybolt

From M8 to M16, this anchor is unlike other heavy-duty expansion anchors. The principle of drawing an expansion sleeve over a tapered cone to create a friction grip is the same, but the Liebig Safetybolt benefits from a secondary cone at the top of the expansion sleeve. Once primary expansion has taken place at the bottom of the anchor, this also expands. The result is more uniformed expansion over a greater surface area -mimproving its hold and resistance to applied tension loads.

The anchor also has a much thicker sleeve compared to the market standard, resulting in the anchor offering much higher shear performance.

Another feature of the Liebig Safetybolt is the domed washer under the nut or bolt head. This becomes flattened when the anchor is tightened to the correct torque and shows a relaxation back to its original shape when the torque is reduced or removed. Making it much easier to identify correct installation and also for inspection afterwards

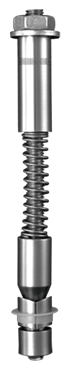

Liebig anchor

More comparable to other heavy-duty anchors within price-sensitive markets, this product still offers unique features such as its three-piece expansion shield which generates a more uniformed single point expansion.

This anchor, like the Liebig Safetybolt, also benefits from the feature of the dome washer under the nut or bolt head.

Modularity:

All Liebig anchors are modular in design and application specific assemblies are easily and cost-effectively produced within a minimal lead time. They can be modified to increase anchorage depth or to enable them to hold down much thicker fixtures. Because they are manufactured using higher grade materials, higher tensile and shear loads are easily achieved