UKTA offers a new dawn for building safety and sustainability

After many years of designing and sourcing components using European Technical Assessments (ETAs) as the dependable marker for safety and performance on non-harmonised products, the arrival of a new technical assessment in the form of the UKTA is understandably raising questions about why it is necessary and how the new regulatory landscape will differ.

Firstly, it is important to understand what a UKTA is. The “United Kingdom Technical Assessment” is the means for non-harmonised products to achieve UKCA Marking, making it the UK equivalent of ETAs (European Technical Assessments) which are needed to achieve CE Marking in Europe.

Importantly, the UKTA confirms that a product is suitable for the UK market and initially requires that it meets the same performance criteria set out in the ETA (European Technical Assessment). This is an approval that EJOT is extremely familiar with as many of our construction fasteners, whether that be concrete anchors, through-bolts, concrete screws or building envelope fasteners, have held ETA approval for decades.

The only UK body eligible to approve UKTA certification is the British Board of Agrément (BBA) – an organisation well-known and respected in the construction sector, and one that is focused on helping the industry create a world-class built environment. So, in terms of the process for securing an UKTA, that inspires confidence that the new mark will have the credibility it requires.

But why is the UKTA needed when the ETA is equivalent? It is important to consider that the UK Government is required to satisfy the requirements of the Building Safety Act, which has emerged following the Hackitt Report, and without doubt the UK construction industry is going to change as a result. The advent of the UKTA is one of the strategic first steps that will be needed to adhere to a vision for safety and sustainability. In short, we have no second chances as an industry – we have to get this right.

Whilst designers, engineers, specifiers, and contractors have a responsibility to work within best practice parameters, they need to be able to reference the very latest standard appropriate and applicable to country of application origin – in this instance construction projects happening within the UK borders. And having UK specific standards in many ways eliminates potential grey areas.

With the UKTA, therefore, we now have an up-to-date reference point from which we can work, satisfying with confidence new construction regulations, where accountability and key performance criteria is the overriding focus. At EJOT, we think this is a pivotal moment to change the UK construction industry to be more accountable and provide clarity of information.

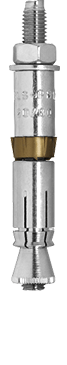

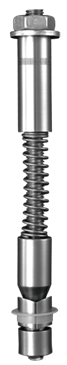

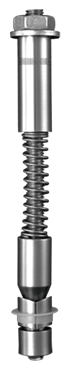

This is why we have worked to secure a UKTA early for our key concrete anchoring product, the LIEBIG Superplus BLS. Given that this heavy-duty anchor is used in safety critical applications including in the nuclear power industry, it was important there was no uncertainty regarding the product’s suitability during the regulatory transition. And it will be the first of many to be UKTA certified.

So, when it comes to making decisions on the specification of products, we only see positives for those which are UKTA certified. This is because the approval process stipulates an overriding standard for product data, and in what context that data should be judged in reference to specification. And all product manufacturers must adhere to this standard. That means that specification decisions can be made on a like for like basis providing a higher degree of accuracy assurance.

In terms of concrete anchoring, pre-ETA there was no standard other than the CCD method (Concrete Capacity design). Some of this data was included into the ETA to standardise data, along with other measures to level up the data being supplied for specification. Now we have a standard that provides clarity and transparency that equally sets a standard for product-to-market data now and in the years ahead.

Ultimately this means specifiers will get confirmation of a product’s performance and reassurance that what you see is what you will get. This allows designers and engineers to view complete data knowing that products have been tested and assessed in exactly the same way.

As we move forward to design and build in a way that delivers safer, more sustainable, and higher quality outcomes, clarity with regard to information and regulatory compliance will be key. We think, therefore, that UKTAs assessed by authoritative bodies like the BBA enable the construction industry to take a big step in the right direction.

The LIEBIG Superplus BLS anchor is widely used in nuclear power plants due to its extended seismic approvals, including those beyond the ETA, by demonstrating its suitability for continued specification and use in light of the transition from CE marking to the UKCA mark.

Variants within the Superplus BLS family also include a countersunk version, pre-installation options, and reduced embedment options where rebar is to be avoided.

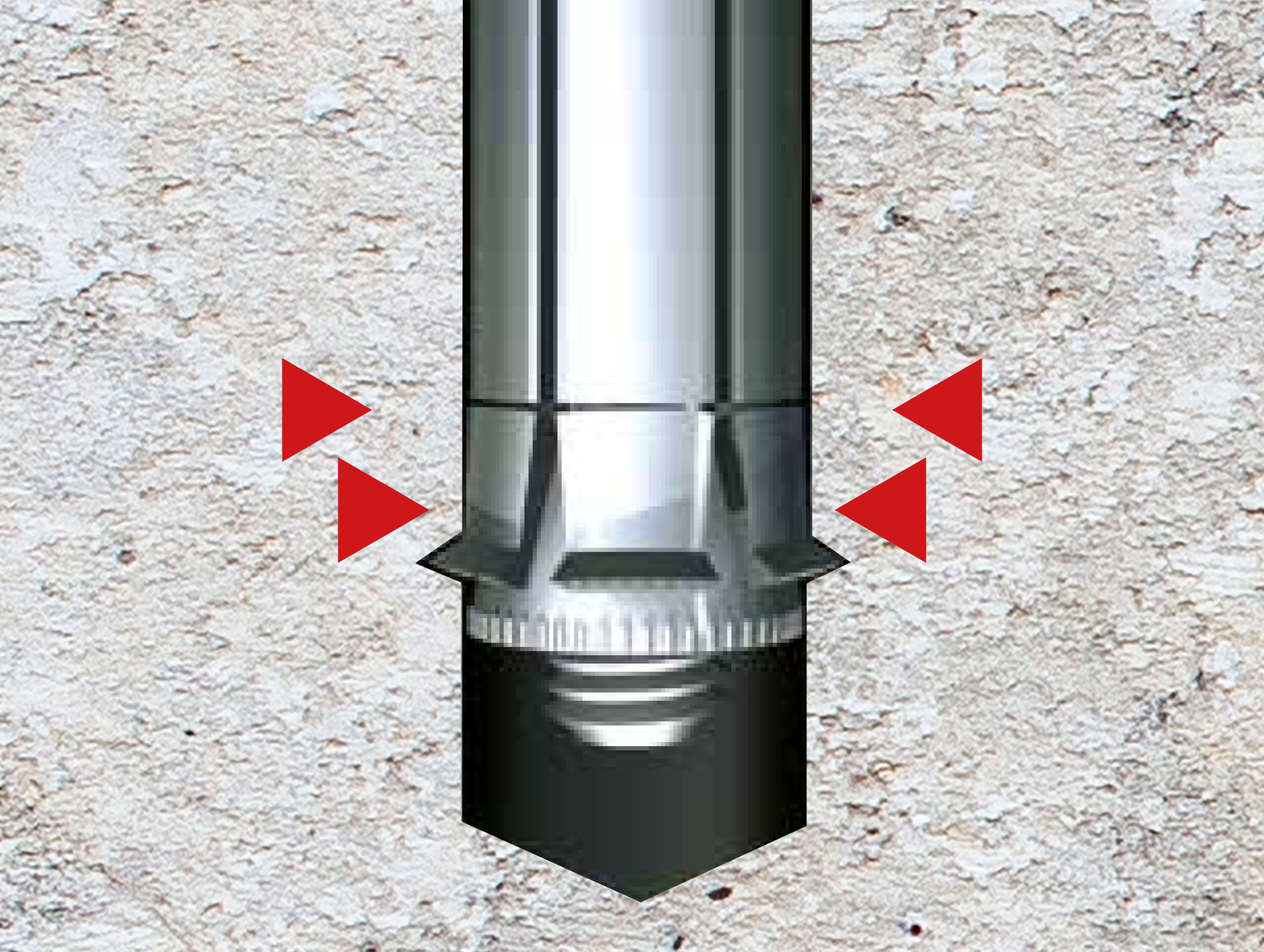

Installers can work more efficiently and achieve consistent quality with Superplus BLS because it does not require an exact hole depth to achieve a secure fixing – teeth on the anchor’s innovative sleeve will always engage to deliver a durable mechanical interlock.